Jan 2013

Panhard crankshaft jig

Sunday 13 January 2013 Filed in: Blog Comments | Panhard Crankshaft

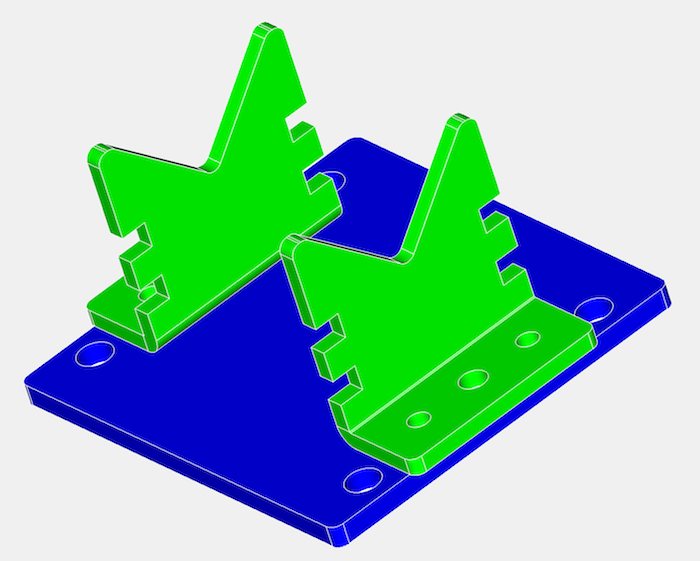

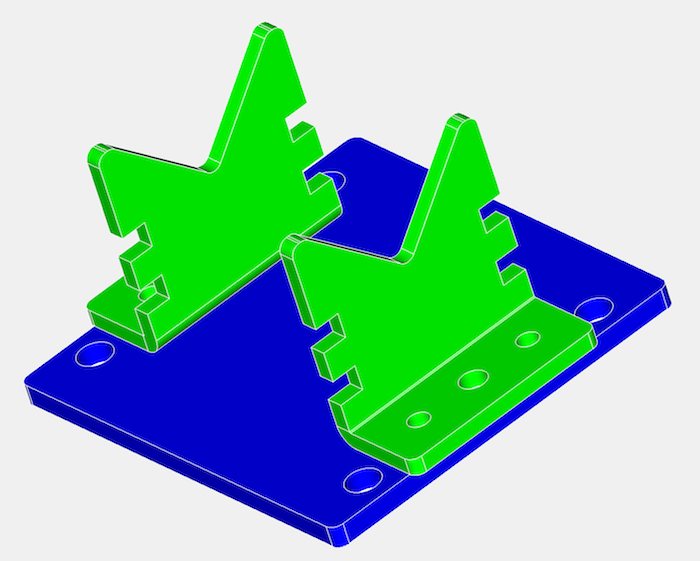

I need to make a jig to hold the crankshaft on the mill bed. I could set it up using fee blocks, but I decided if I made a dedicated jig, I could reliably and consistently machine the two holes required for pinning 180º apart. If I machine to the same depth using the digital readout, then the crankshaft should stay in balance. After looking at the problem, I decided a session at the laser cutters would be more than adequate. This is what I had in mind in CAD, without the clamping mechanism being shown.

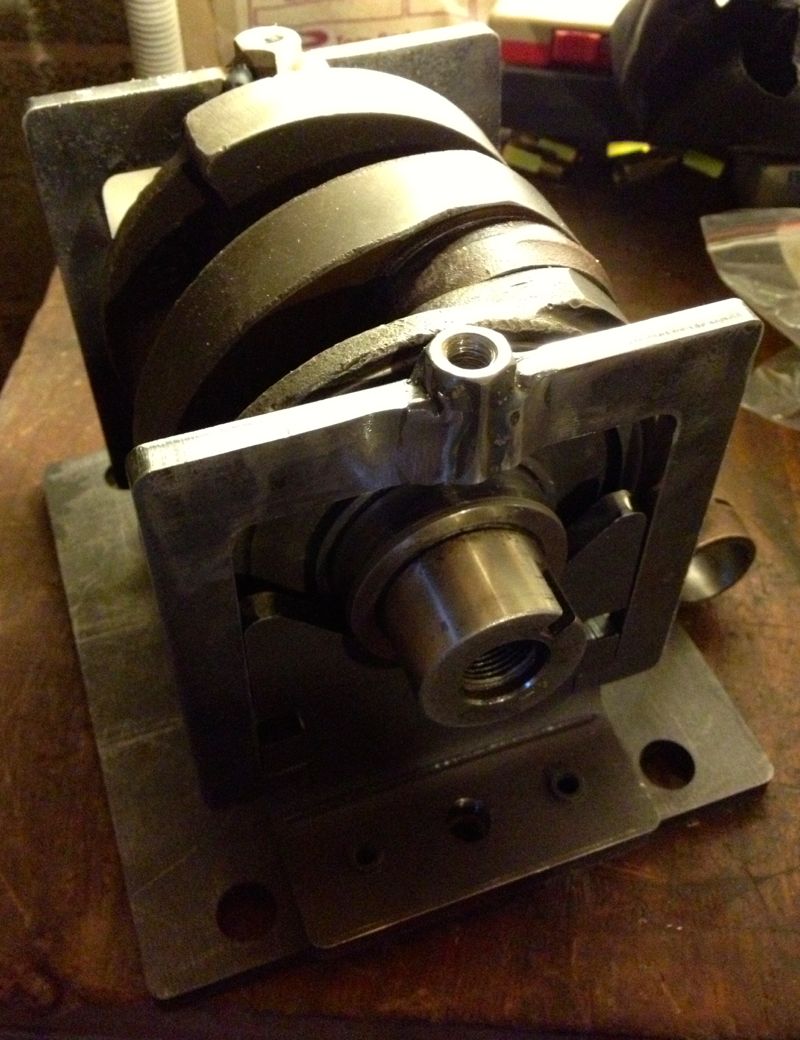

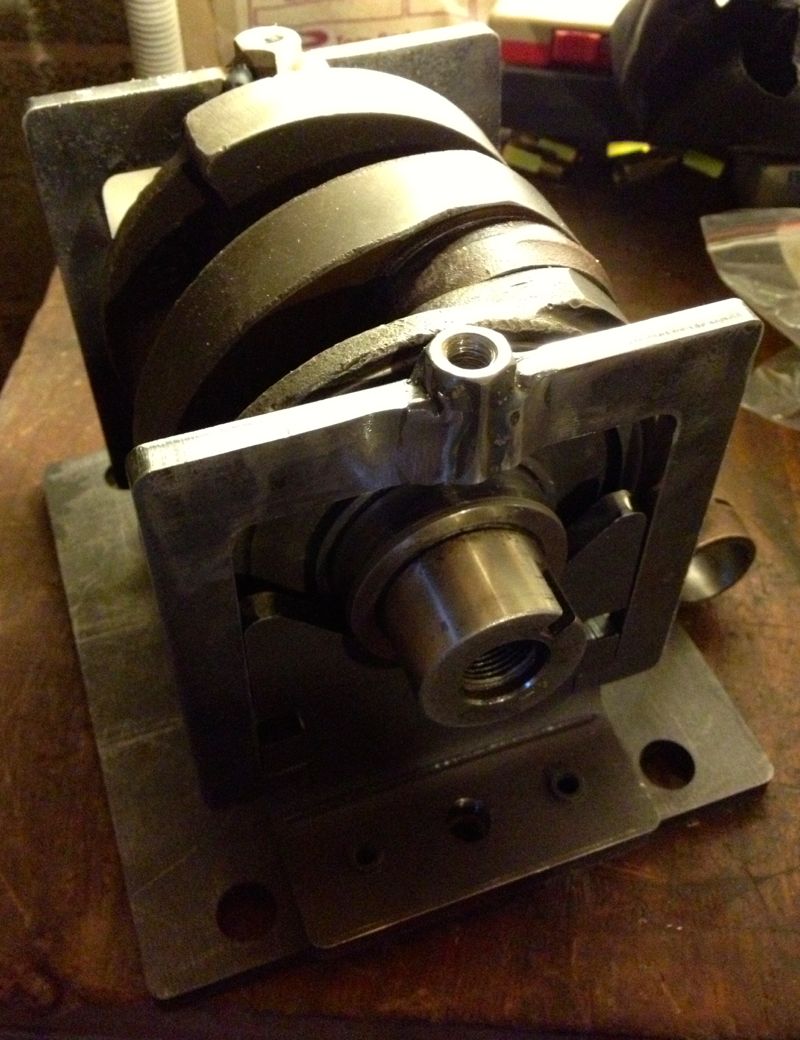

This is the first attempt, just waiting for a few fasteners, as the shop had closed by the time I picked the parts up.

I am going to modify it further with a quick change indexing system to give a 180º setting, but first I have to put it on the mill bed, and explore the tool path fit. The Clarkson MT40 collet holder is quite large, and I now need a slightly longer carbide slot drill to get machine the required hole depth for the dowelling process. the dowels are specially made for the job, and to aid removal, I have gone for the internally threaded type to aid crankshaft rebuilding operations.

It won’t be long before I can pin the crankshafts properly.

UPDATE I am going to use a small boring bar now, I tried with a slot drill, and it “walked” and the hole was too large!

This is the first attempt, just waiting for a few fasteners, as the shop had closed by the time I picked the parts up.

I am going to modify it further with a quick change indexing system to give a 180º setting, but first I have to put it on the mill bed, and explore the tool path fit. The Clarkson MT40 collet holder is quite large, and I now need a slightly longer carbide slot drill to get machine the required hole depth for the dowelling process. the dowels are specially made for the job, and to aid removal, I have gone for the internally threaded type to aid crankshaft rebuilding operations.

It won’t be long before I can pin the crankshafts properly.

UPDATE I am going to use a small boring bar now, I tried with a slot drill, and it “walked” and the hole was too large!

Comments

Panhard external oil filter conversion - screw on filter update

Wednesday 02 January 2013 Filed in: Blog Comments | Panhard Oil

A lot of time has gone by since I did my first oil filter conversion, the first ten kits used a Champion F129 filter, whereas the later ones had a different thread and used a M20 x 1.5mm Renault Purflux filter.

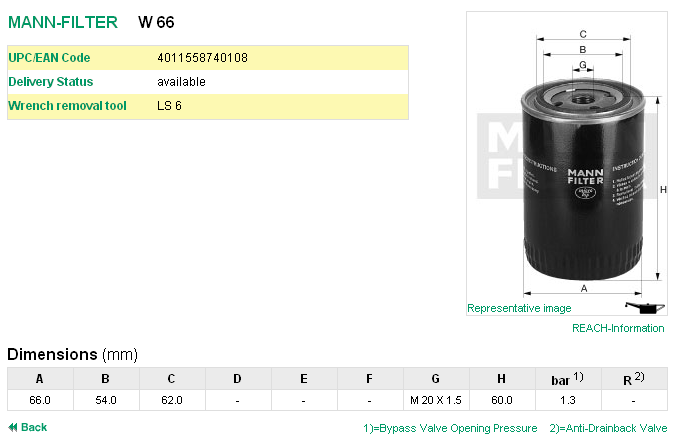

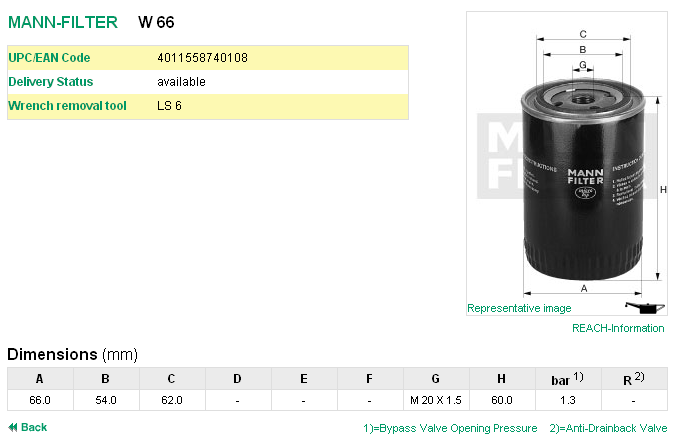

At the time the economics of making a special filter for the cars was out of the question, so it was necessary to remove the anti drain valve membrane fitted to the Purflux aka Renault Clio unit. Later on I made an internal filter version, but when I made a few external filter kits later I used a Mann Hummel W66. Details as below, but the picture is not representational, as it is only 60mm high. It is fitted with a bypass valve, which allows oil to flow should the filter clog up sufficiently to restrict the oil flow, but this is only really needed in high flow shell bearing crankshafts. In the Panhard engine, the low flow requirements and the low mileage usage they see means that the oil and filter would be changed before the bypass valve could operate, and besides the oil light would illuminate more frequently if this was happening.

One of the areas that was an improvement on the very first filter kit design was the dished area of the sump plate that received the filter cartridge was increased, so that meant there was more scope for larger diameter screw on filters.

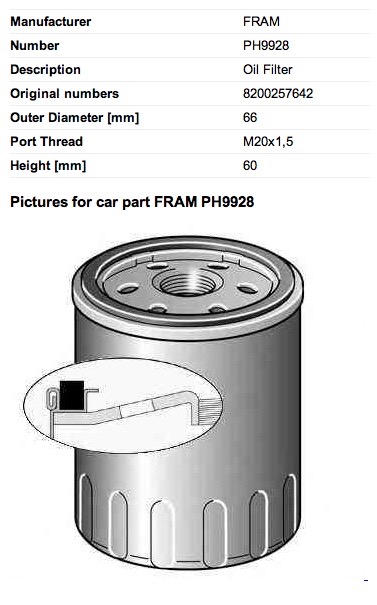

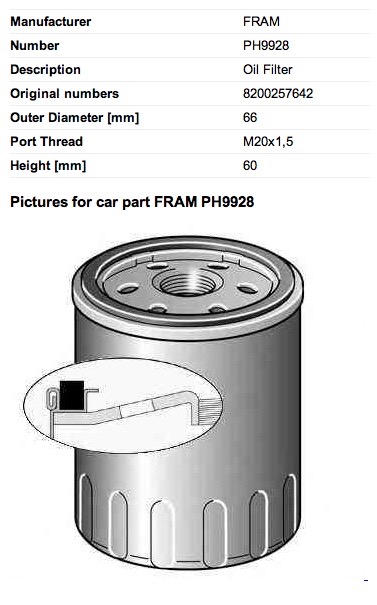

A UK PL17 owner, Gary Ockenden, who is involved in the motor trade recommended a Fram 9928, which is shown below (the picture is not representational), and this is an alternative for the Purflux LS924 & Mann Hummel W66.

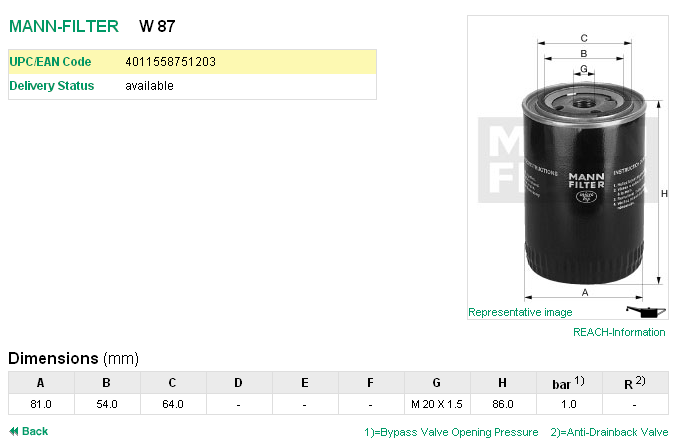

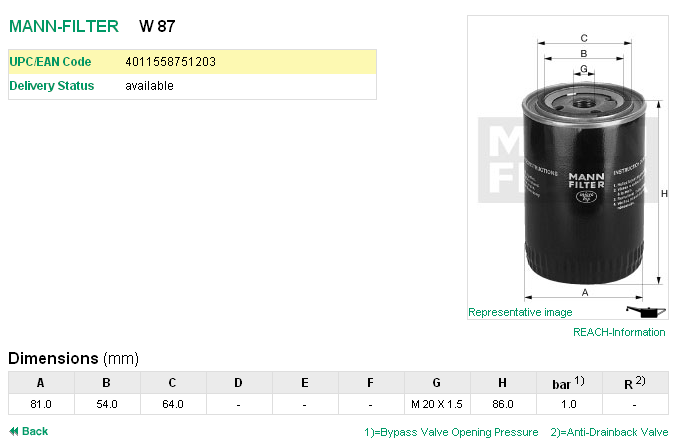

Another filter that can be used is a Mann Hummel W87, but this is some 26mm taller than the W66.

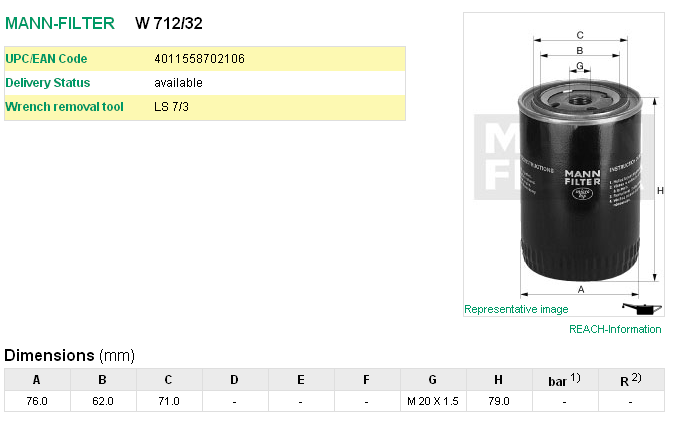

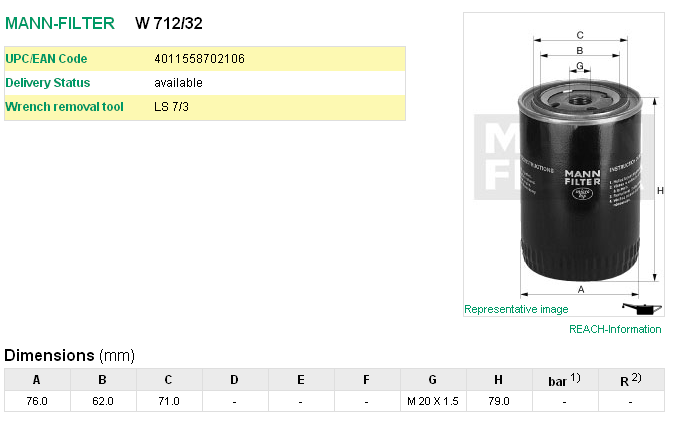

However the best filter, which has no bypass valve or anti drain valve fitted, so it is ideal on the suction side, is the Mann Hummel W712/32, but this is slightly taller by 19mm over the W66, and so better suited to the PL17 models. This model has a larger diameter as well, and so holds more oil.

The Mann 712/32 filter is also cross referenced to these numbers.

Ford 5022 739

Opel 650386

Vauxhall VOF114

GM 93156652 or 93156659

At the time the economics of making a special filter for the cars was out of the question, so it was necessary to remove the anti drain valve membrane fitted to the Purflux aka Renault Clio unit. Later on I made an internal filter version, but when I made a few external filter kits later I used a Mann Hummel W66. Details as below, but the picture is not representational, as it is only 60mm high. It is fitted with a bypass valve, which allows oil to flow should the filter clog up sufficiently to restrict the oil flow, but this is only really needed in high flow shell bearing crankshafts. In the Panhard engine, the low flow requirements and the low mileage usage they see means that the oil and filter would be changed before the bypass valve could operate, and besides the oil light would illuminate more frequently if this was happening.

One of the areas that was an improvement on the very first filter kit design was the dished area of the sump plate that received the filter cartridge was increased, so that meant there was more scope for larger diameter screw on filters.

A UK PL17 owner, Gary Ockenden, who is involved in the motor trade recommended a Fram 9928, which is shown below (the picture is not representational), and this is an alternative for the Purflux LS924 & Mann Hummel W66.

Another filter that can be used is a Mann Hummel W87, but this is some 26mm taller than the W66.

However the best filter, which has no bypass valve or anti drain valve fitted, so it is ideal on the suction side, is the Mann Hummel W712/32, but this is slightly taller by 19mm over the W66, and so better suited to the PL17 models. This model has a larger diameter as well, and so holds more oil.

The Mann 712/32 filter is also cross referenced to these numbers.

Ford 5022 739

Opel 650386

Vauxhall VOF114

GM 93156652 or 93156659

Panhard camshaft timing gears

Tuesday 01 January 2013 Filed in: Blog Comments

I was having a conversation with a fellow Panhard enthusiast, and he was querying the modifications to the timing gear oil level I make. At the end of the conversation, it was mentioned whether I had seen the modified DB timing gears, to which I said no. Later that day, I received some pictures via email.

What’s really interesting, is I could never understand why the aluminium timing gear that replaces the fibre one was made the same width, as aluminium is so much stronger than the fibre aka Celeron gear. Looking at this DB gear, which is made in steel the racing guys took that to its logical conclusion, and reduced the width. This reduces the pumping losses too, as well as the inertial ones, so it seems there is scope for improvements here too.

Notice the extra mounting holes in the new gear, six versus three, which might have been some further camshaft timing adjustment mechanism.

Thank you Stefaan for the picture.

What’s really interesting, is I could never understand why the aluminium timing gear that replaces the fibre one was made the same width, as aluminium is so much stronger than the fibre aka Celeron gear. Looking at this DB gear, which is made in steel the racing guys took that to its logical conclusion, and reduced the width. This reduces the pumping losses too, as well as the inertial ones, so it seems there is scope for improvements here too.

Notice the extra mounting holes in the new gear, six versus three, which might have been some further camshaft timing adjustment mechanism.

Thank you Stefaan for the picture.