Panhard crankshaft jig

Sunday 13 January 2013 Filed in: Blog Comments | Panhard Crankshaft

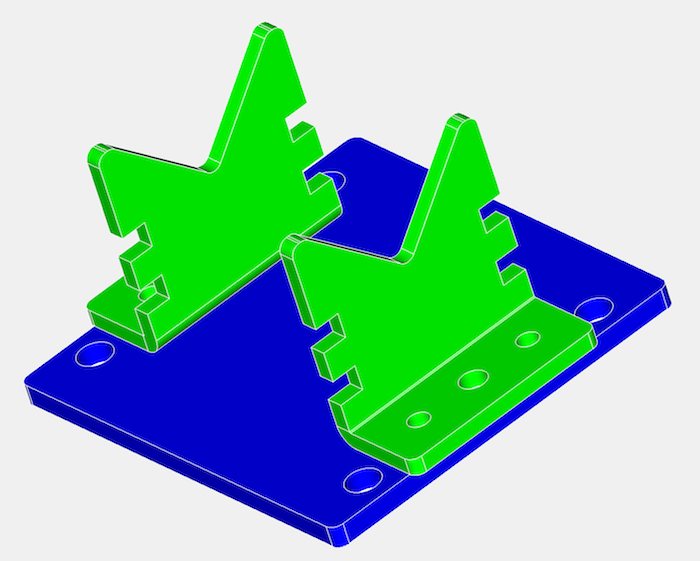

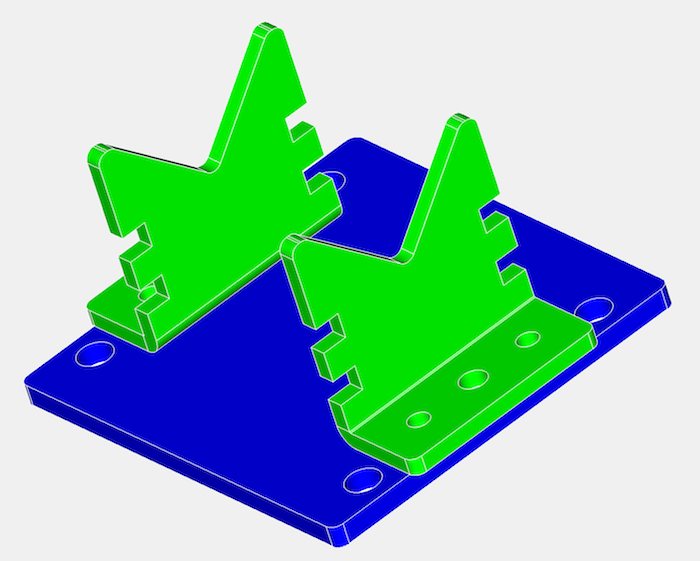

I need to make a jig to hold the crankshaft on the mill bed. I could set it up using fee blocks, but I decided if I made a dedicated jig, I could reliably and consistently machine the two holes required for pinning 180º apart. If I machine to the same depth using the digital readout, then the crankshaft should stay in balance. After looking at the problem, I decided a session at the laser cutters would be more than adequate. This is what I had in mind in CAD, without the clamping mechanism being shown.

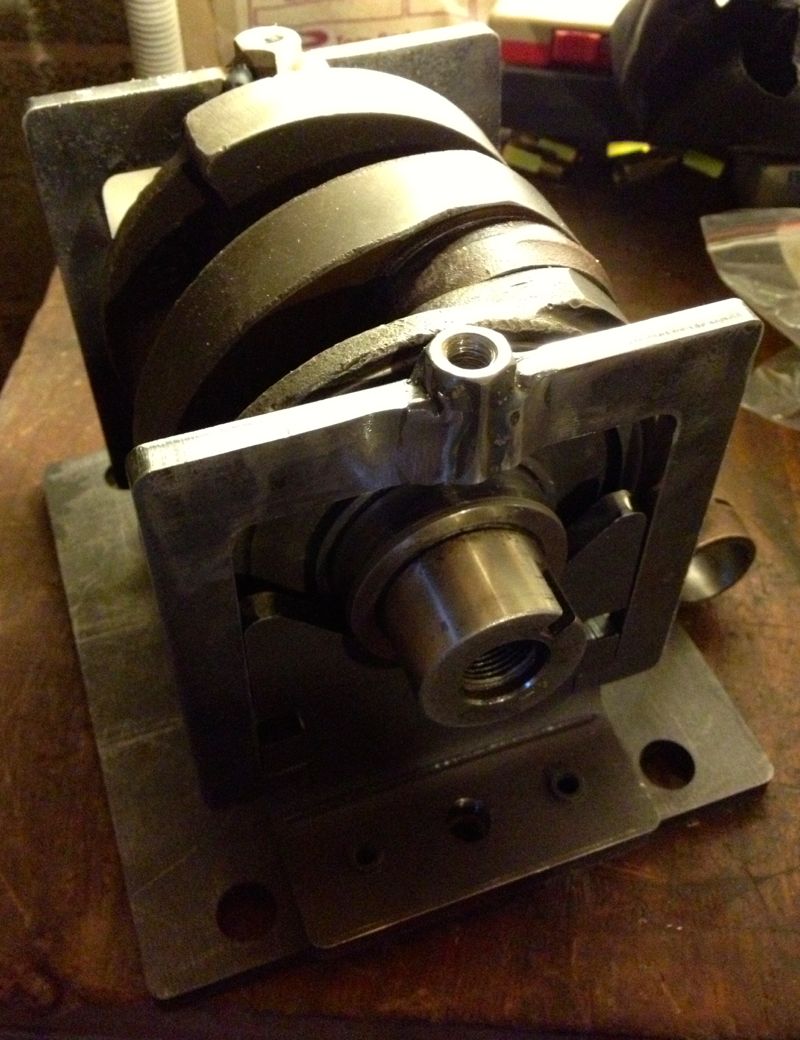

This is the first attempt, just waiting for a few fasteners, as the shop had closed by the time I picked the parts up.

I am going to modify it further with a quick change indexing system to give a 180º setting, but first I have to put it on the mill bed, and explore the tool path fit. The Clarkson MT40 collet holder is quite large, and I now need a slightly longer carbide slot drill to get machine the required hole depth for the dowelling process. the dowels are specially made for the job, and to aid removal, I have gone for the internally threaded type to aid crankshaft rebuilding operations.

It won’t be long before I can pin the crankshafts properly.

UPDATE I am going to use a small boring bar now, I tried with a slot drill, and it “walked” and the hole was too large!

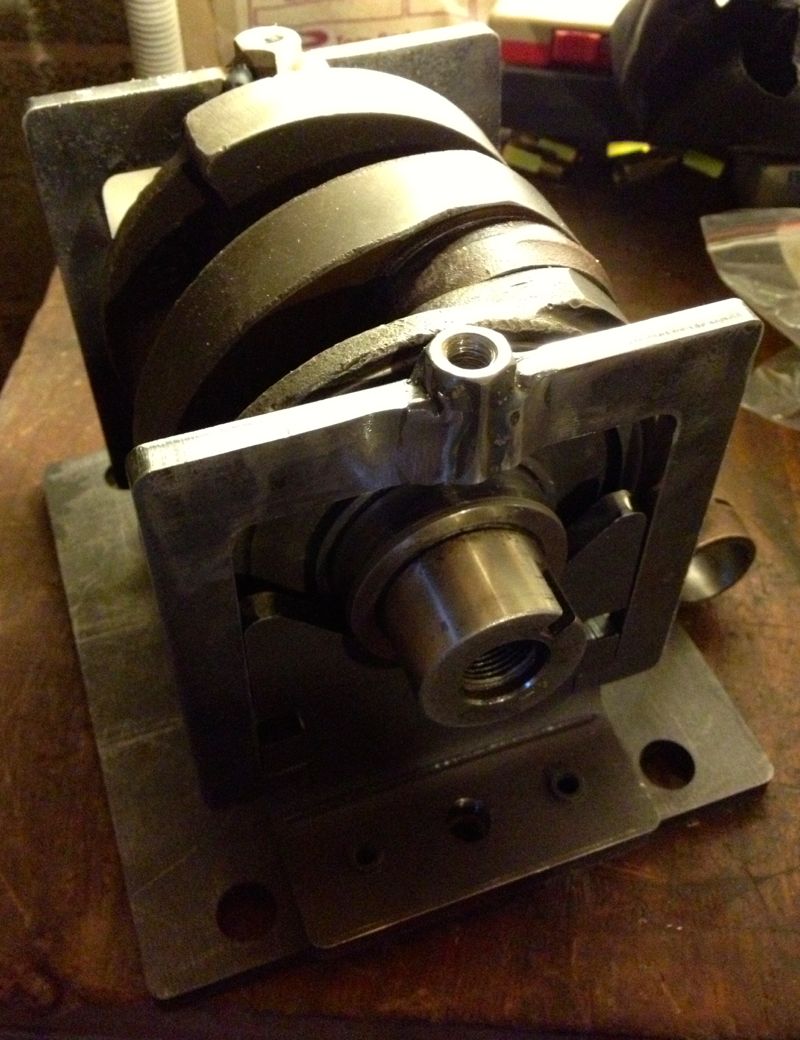

This is the first attempt, just waiting for a few fasteners, as the shop had closed by the time I picked the parts up.

I am going to modify it further with a quick change indexing system to give a 180º setting, but first I have to put it on the mill bed, and explore the tool path fit. The Clarkson MT40 collet holder is quite large, and I now need a slightly longer carbide slot drill to get machine the required hole depth for the dowelling process. the dowels are specially made for the job, and to aid removal, I have gone for the internally threaded type to aid crankshaft rebuilding operations.

It won’t be long before I can pin the crankshafts properly.

UPDATE I am going to use a small boring bar now, I tried with a slot drill, and it “walked” and the hole was too large!

blog comments powered by Disqus