2 January 2014

More updates on the Panhard fuel injection project, which has been slowed by the Christmas break.

The last few weeks I have been evaluating trigger & sensor input variations to make the triggering as robust as possible. The electronics side has been had led by my good friend Jean Paul Cesar, who in an earlier half life was an electronics engineer for Alcatel in France. Skilled & patient though he is, he had to put up with my dopiness on a few occasions, but at least we got there in the end.

So what's the latest. The Imfsoft Ignition and my timing cover solution are designed to work with each other. I chose the Imfsoft not just because of its low cost, but also for the refinements the other options like MAP, knock, curve switching and temperature functions can add.

As a result, the timing cover had to have a single trigger point & two ignition sensors to operate, which is OK for an Imfsoft ignition, but it's not really ideal for fuel injection, although quite a few V twin motorcycles still operate like this. it would appear people always get hung up on this point & quote poor resolution, imprecise timing, and other things to support their arguments, but when you compare this with the systems on the original engine, the argument is somewhat superfluous. That being said, better resolution is generally a positive, and in a high revving multi cylinder racing engine it carries more weight than it does on a two cylinder one.

All the testing to date has been on Brian's 2012 engine, and the test rig. In reality, although it is relatively easy to machine pulleys, drill and tap aluminium gears, I was never happy with this as a procedure suitable for less able people. The majority of Panhard owners want a turn key approach, and my solution wasn't as simple as it could be. Everything is a compromise, and the proximity of the turbine (engine fan) to the sensor head, limits the depth I have to play with, but a more compact sensor was over four times the price and as you need two of them it added significant cost to a low volume product.

As the typical owner is not au fait with current adhesive technology, the only simplification I could offer was a laser cut template to assist the positioning of the steel trigger pin. It is a relatively easy task to mark the gear and drill it, when the part is new and out of the car, but what if you wanted to install the system in situ. That was a whole new can of worms, and it forced a rethink, and going back over earlier decisions.

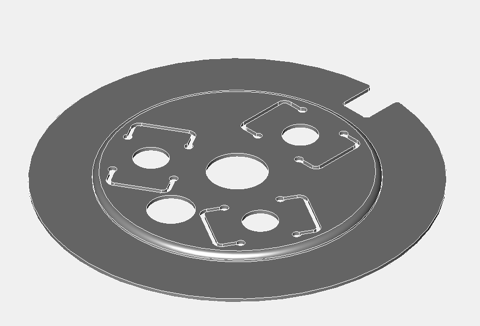

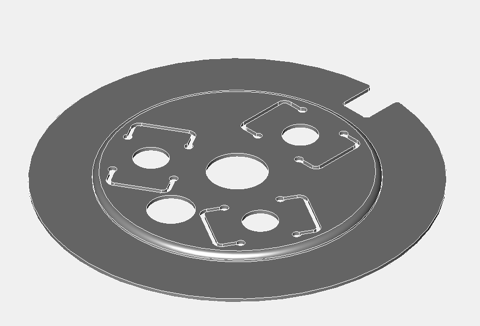

The result is this...which is a combined steel tab washer & trigger in one unit.

The best bit it has genuinely made the whole system much easier to install. It's not fully finished yet, as I need to configure the slot so that I cover all camshaft variants, and it must lie at least 30º ahead of the sensor at TDC, but essentially all that is required nowise the engine be placed at TDC, the original tab washer and three screws that hold the camshaft gear onto the camshaft be removed, the new timing wheel cum tab washer be refitted, slot in the right hand corner, and it is done. If you have the wrong cam phase, just swap the the sensor connectors over, and you're almost good to go. It will probably take a verification of the ignition timing using a strobe, just to double check the engine timing and the computer timing (offset) is the same, but that's just good practice.

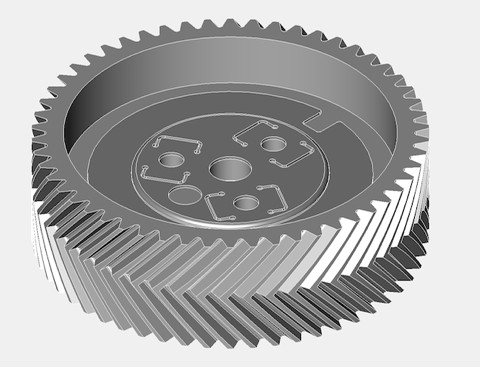

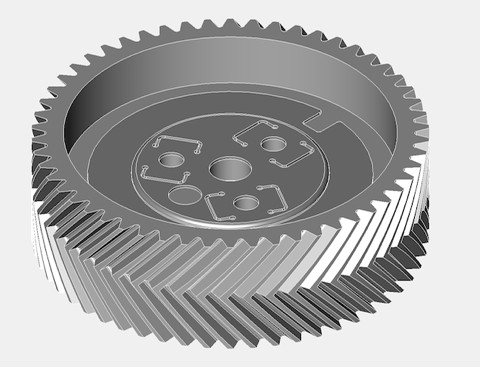

This is how the timing wheel sit in the aluminium camshaft gear.

The ears around the three holes are the tabs you can bend up to lock the screws in place, which to be fair are overkill, given the range of Loctite & similar products available today.

More updates on the Panhard fuel injection project, which has been slowed by the Christmas break.

The last few weeks I have been evaluating trigger & sensor input variations to make the triggering as robust as possible. The electronics side has been had led by my good friend Jean Paul Cesar, who in an earlier half life was an electronics engineer for Alcatel in France. Skilled & patient though he is, he had to put up with my dopiness on a few occasions, but at least we got there in the end.

So what's the latest. The Imfsoft Ignition and my timing cover solution are designed to work with each other. I chose the Imfsoft not just because of its low cost, but also for the refinements the other options like MAP, knock, curve switching and temperature functions can add.

As a result, the timing cover had to have a single trigger point & two ignition sensors to operate, which is OK for an Imfsoft ignition, but it's not really ideal for fuel injection, although quite a few V twin motorcycles still operate like this. it would appear people always get hung up on this point & quote poor resolution, imprecise timing, and other things to support their arguments, but when you compare this with the systems on the original engine, the argument is somewhat superfluous. That being said, better resolution is generally a positive, and in a high revving multi cylinder racing engine it carries more weight than it does on a two cylinder one.

All the testing to date has been on Brian's 2012 engine, and the test rig. In reality, although it is relatively easy to machine pulleys, drill and tap aluminium gears, I was never happy with this as a procedure suitable for less able people. The majority of Panhard owners want a turn key approach, and my solution wasn't as simple as it could be. Everything is a compromise, and the proximity of the turbine (engine fan) to the sensor head, limits the depth I have to play with, but a more compact sensor was over four times the price and as you need two of them it added significant cost to a low volume product.

As the typical owner is not au fait with current adhesive technology, the only simplification I could offer was a laser cut template to assist the positioning of the steel trigger pin. It is a relatively easy task to mark the gear and drill it, when the part is new and out of the car, but what if you wanted to install the system in situ. That was a whole new can of worms, and it forced a rethink, and going back over earlier decisions.

The result is this...which is a combined steel tab washer & trigger in one unit.

The best bit it has genuinely made the whole system much easier to install. It's not fully finished yet, as I need to configure the slot so that I cover all camshaft variants, and it must lie at least 30º ahead of the sensor at TDC, but essentially all that is required nowise the engine be placed at TDC, the original tab washer and three screws that hold the camshaft gear onto the camshaft be removed, the new timing wheel cum tab washer be refitted, slot in the right hand corner, and it is done. If you have the wrong cam phase, just swap the the sensor connectors over, and you're almost good to go. It will probably take a verification of the ignition timing using a strobe, just to double check the engine timing and the computer timing (offset) is the same, but that's just good practice.

This is how the timing wheel sit in the aluminium camshaft gear.

The ears around the three holes are the tabs you can bend up to lock the screws in place, which to be fair are overkill, given the range of Loctite & similar products available today.

25 December 2013

Another update on the Panhard fuel injection project, which has been on my radar for a few years, but finally it’s getting there.

The most important bit with any fuel injection system is to have reliable triggering at all speeds, and the missing tooth trigger wheel works OK, but the simple version is prone to noise, especially when I hook up the ignition coils and using the MicroSquirt v2 boxes. It is stable to 10K without, and also when using the MicroSquirt v3 with a pull up resistor.

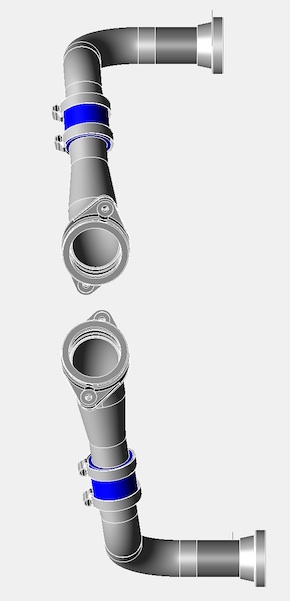

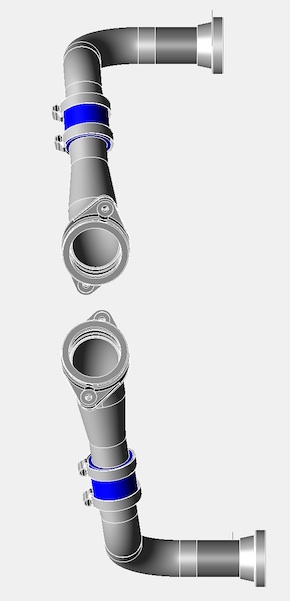

The intake manifold is completed except for some cosmetic details, tidying up the prototype welds, and welding the inlet stubs into place. They don’t incorporate my new O ring detail yet, as I am evaluating the fit on different cylinders before committing to the final design, but this will banish the air leaks these engines can suffer from.

Overall the new intake manifold is very rigid, without a middle support brace, and there is a little work to do with the clutch brackets etc for the 24 models. The inlet stubs have been modified to allow for easier fitment over the heater rubbers aka the “gas masks”, although the last generation 24 models will need to cut the manifold and joint them with a fluoro-silicon connector, as in the picture below.

First thing you will notice from this view, is the left & right inlet manifolds are finally the same length, something that has always affected the original cars, as they had one inlet manifold 40mm longer, which dilutes the camshaft timing effects.

That’s all for now, Merry Christmas, and Happy Panharding in the New Year.

Another update on the Panhard fuel injection project, which has been on my radar for a few years, but finally it’s getting there.

The most important bit with any fuel injection system is to have reliable triggering at all speeds, and the missing tooth trigger wheel works OK, but the simple version is prone to noise, especially when I hook up the ignition coils and using the MicroSquirt v2 boxes. It is stable to 10K without, and also when using the MicroSquirt v3 with a pull up resistor.

The intake manifold is completed except for some cosmetic details, tidying up the prototype welds, and welding the inlet stubs into place. They don’t incorporate my new O ring detail yet, as I am evaluating the fit on different cylinders before committing to the final design, but this will banish the air leaks these engines can suffer from.

Overall the new intake manifold is very rigid, without a middle support brace, and there is a little work to do with the clutch brackets etc for the 24 models. The inlet stubs have been modified to allow for easier fitment over the heater rubbers aka the “gas masks”, although the last generation 24 models will need to cut the manifold and joint them with a fluoro-silicon connector, as in the picture below.

First thing you will notice from this view, is the left & right inlet manifolds are finally the same length, something that has always affected the original cars, as they had one inlet manifold 40mm longer, which dilutes the camshaft timing effects.

That’s all for now, Merry Christmas, and Happy Panharding in the New Year.

12 December 2013

I am not ready to go public on my new EFI project, but the basic inlet manifold mods are done. I am trying to acquire the right connectors, so in the meantime I am resurrecting the "engine test rig", seen in the picture above. Using a sample two hole sensor timing cover, I will first check the Imfsoft Direct Ignition unit is functioning on Brian's engine, and then switch to the MicroSquirt module and start testing the "dual spark" B&G firmware. The beauty of this is I can use the same trigger & sensor set up for both the Imfsoft ignition and the MicroSquirt injection, and this helps test the future proofing I had in mind when I first drew up the concept.

The fuel pump system has arrived, and it appears to be workable, it’s the third one I’ve bought so far. Annoyingly, there is yet another bespoke connector to source, but hopefully I shall be drawing the tools and parts I need to complete this part of the installation and confirm the tank measurements.

I have to say it's looking good at the moment, but ideally I really need an aluminium timing camshaft gear to convert my old 24C engine.

I am not ready to go public on my new EFI project, but the basic inlet manifold mods are done. I am trying to acquire the right connectors, so in the meantime I am resurrecting the "engine test rig", seen in the picture above. Using a sample two hole sensor timing cover, I will first check the Imfsoft Direct Ignition unit is functioning on Brian's engine, and then switch to the MicroSquirt module and start testing the "dual spark" B&G firmware. The beauty of this is I can use the same trigger & sensor set up for both the Imfsoft ignition and the MicroSquirt injection, and this helps test the future proofing I had in mind when I first drew up the concept.

The fuel pump system has arrived, and it appears to be workable, it’s the third one I’ve bought so far. Annoyingly, there is yet another bespoke connector to source, but hopefully I shall be drawing the tools and parts I need to complete this part of the installation and confirm the tank measurements.

I have to say it's looking good at the moment, but ideally I really need an aluminium timing camshaft gear to convert my old 24C engine.