Mar 2013

Panhard Oil Lubrication Musings

Friday 15 March 2013 Filed in: Panhard Oil

I am writing this piece to try and get past some misconceptions some people seem to have about Panhard engines and their oil circuits. I will edit this over the next few weeks, and try and make this easier to grasp, and I hope to translate a little of this for my French friends who visit my website.

Panhard engines evolved over time, as they needed more horsepower and had to respond to service failures. The single biggest lubrication change came to the front cylinder crankshaft oil circuit, which was modified and adapted to cure a premature wear problem to this cylinders big end bearings.

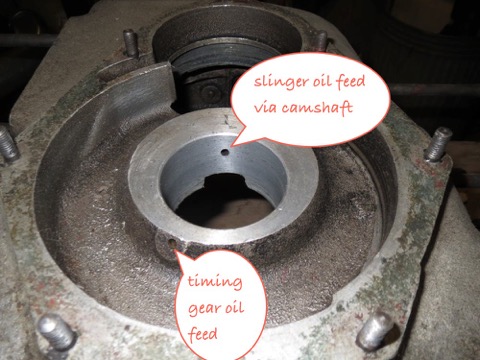

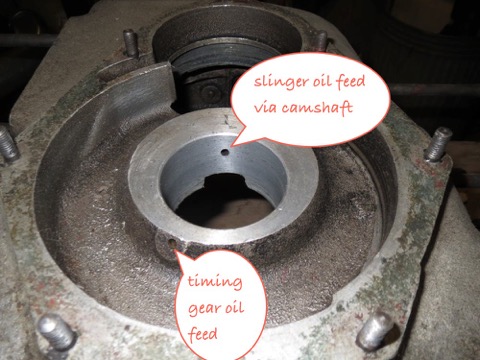

Originally the oil system was well designed, but a misplaced hole marginalised the oil supply at the front of the crankshaft compared to the rear. The oil supply to the timing gears was the problem, as can be seen in the picture below, labelled timing gear oil feed. This hole lowered the oil pressure to the slinger oil feed via the camshaft, so as the pump output dropped, the oil supply became deficient enough to accelerate the wear and cause service failures.

The later engines, had a modified oil delivery system, where the slinger oil feed was removed, and all the oil went into the timing gear case, and relied on the churning of the gears to splash lubricate and purge the oil into the slingers via two new high level holes. These are shown in the picture below, and labelled oil feed to slingers. The original drain holes that returned oil to the sump were filled in or not made.

All that is needed to restore the oil to how it should have been designed, is to plug the timing gear oil feed and replace this with a central or common feed from the camshaft oil gallery. This is easily achieved by modifying or replacing the oil light piston with a bespoke design.

I had done this previously to various engines over the last few years, but refined it to include a bypass valve inside the oil light, so maintain a good pressure in the camshaft oil gallery. The small hole sprays an oil mist into the timing gear cavity, and lubricates the camshaft and crankshaft gear.

I also fitted a new nose to this, made of brass, but it wasn’t necessary, because there was no adverse wear to the other component.

UPDATE 15 September 2013

Lately, I have modified the design further by enlarging the hole, and using it as the oil pump pressure relief valve, that way the pumped oil isn’t wasted it used to lubricate the timing gears. The only thing I should point out, is that I create a lower oil return, so I don’t saturate the timing gears in oil and incur churning losses. Typical splash lubrication system, don’t immerse more than a third of the gear diameter.

I made the holes here on the 2012 engine, but I now make them slightly lower. As this was a M10 engine, I had to plug the slinger oil feeds with an M8 set screw & a dab of Loctite, and I also restored the original camshaft oil feed that passed through the crankcase, and made a new exit under the bearing. I also enlarged the hole slight at the camshaft interface to equalise the port timings front and rear, which is something Panhard never did.

Panhard engines evolved over time, as they needed more horsepower and had to respond to service failures. The single biggest lubrication change came to the front cylinder crankshaft oil circuit, which was modified and adapted to cure a premature wear problem to this cylinders big end bearings.

Originally the oil system was well designed, but a misplaced hole marginalised the oil supply at the front of the crankshaft compared to the rear. The oil supply to the timing gears was the problem, as can be seen in the picture below, labelled timing gear oil feed. This hole lowered the oil pressure to the slinger oil feed via the camshaft, so as the pump output dropped, the oil supply became deficient enough to accelerate the wear and cause service failures.

The later engines, had a modified oil delivery system, where the slinger oil feed was removed, and all the oil went into the timing gear case, and relied on the churning of the gears to splash lubricate and purge the oil into the slingers via two new high level holes. These are shown in the picture below, and labelled oil feed to slingers. The original drain holes that returned oil to the sump were filled in or not made.

All that is needed to restore the oil to how it should have been designed, is to plug the timing gear oil feed and replace this with a central or common feed from the camshaft oil gallery. This is easily achieved by modifying or replacing the oil light piston with a bespoke design.

I had done this previously to various engines over the last few years, but refined it to include a bypass valve inside the oil light, so maintain a good pressure in the camshaft oil gallery. The small hole sprays an oil mist into the timing gear cavity, and lubricates the camshaft and crankshaft gear.

I also fitted a new nose to this, made of brass, but it wasn’t necessary, because there was no adverse wear to the other component.

UPDATE 15 September 2013

Lately, I have modified the design further by enlarging the hole, and using it as the oil pump pressure relief valve, that way the pumped oil isn’t wasted it used to lubricate the timing gears. The only thing I should point out, is that I create a lower oil return, so I don’t saturate the timing gears in oil and incur churning losses. Typical splash lubrication system, don’t immerse more than a third of the gear diameter.

I made the holes here on the 2012 engine, but I now make them slightly lower. As this was a M10 engine, I had to plug the slinger oil feeds with an M8 set screw & a dab of Loctite, and I also restored the original camshaft oil feed that passed through the crankcase, and made a new exit under the bearing. I also enlarged the hole slight at the camshaft interface to equalise the port timings front and rear, which is something Panhard never did.

Comments