Panhard Twin Plugging & Ignition Options 1

06/04/13 11:35 Filed in: Panhard Ignition

It is one thing to twin plug a cylinder, it is a totally different thing to get the right quality sparks. There are two options, wasted or sequential twin plugging. I mistakenly thought I could achieve sequential twin plug sparking with double ended coils, when really it would have only been wasted, but it took a French friend to put me straight, thank you Jean Paul.

Originally, I was going to use stick coils, or pencil coils, but the Panhard heads and torsion bar castings do not lend themselves to a satisfactory fixing solution, plus time is running out, and the added complication of angling the spark plugs, using 10mm plugs and a bespoke adaptor seems like a lot of trouble for little gain.

Historically, Hampe did a wasted system over fifty years ago, using four standard coils, two times two wired in parallel, with an additional contact breaker placed inside the distributor, and an added cam to trigger this second set of points. Nowadays this wouldn’t be required, as you could use the OEM sequential points trigger and a modern ignition control module to switch on the additional coils, but this is digressing slightly.

What are the issues with twin plugging? Well it is nicely summed up here, in this article taken from the Vincent Owners Club if I remember correctly.

Now to sparks. Both Roger Haylett and Gordon Colquhoun want to know about double-ended coils and twin sparks - both having had problems. When fitting twin plugs into a head the concept of using a double-ended coil, fitted into the standard ignition system, may seem ideal, but it doesn't work out. Why? Well, examine where the double-ended coils come from. They are invariably from so-called idle-spark systems, where one cylinder is fired on its compression stroke, and the other end is feeding another cylinder, which will be on its induction stroke (though exactly where depends on whether it is a parallel twin, four, or vee-twin). What you need to know is that the voltage required to make a spark depends on the pressure of the gas it is trying to spark through. So, in an idle spark system, the voltage required is only slightly more than in a single-ended one, because one cylinder is under compression (say 150 psi), but the other isn't (ie, less than 15 psi). So almost all of the voltage appears on the firing cylinder, and a very weak, low voltage spark, occurs in the other one (usually not enough energy even to fire a mixture, which is why it works on vee-twins, which can be well on to the induction stroke, and filling with mixture). Try the same coil on a twin plug head and you need twice the voltage, which is way above the design criteria. So it may not fire reliably.

There are a variety of fixes. Best of the lot is to use a pair of coils in series, to drive the two plugs - preferably a pair of identical-type coils, but they don't need to be better matched than that. Of course, this requires half voltage coils- ok if you can find a pair of six volt ones to run on 12 volt (you might look at 12 volt ones with ballast resistors, and bypass the resistors which makes them six-eight volt types). A number of people have told me that, like Gordon, they have run coils in parallel, but theoretically, it isn't a good idea. Coils in parallel need to balance and so too does the sparking voltage of the plugs. If they don't go off together, then the single spark immediately loads one coil, which may suck power from the primary of the other, and the second spark may not occur. So it probably works better than the original double-ended coil, which misfires completely, but you may actually be running single spark some, or all, of the time, and not, necessarily, firing the same plug every time. Optimising the timing may be impossible, if single and twin optima are different, although the engine will not, necessarily, show ignition problems. However, if it works for you, I'm not going to say it doesn't - but I recommend the series arrangement.

If you are trying to do a Twin, then series or parallel, it makes for a lot of coils. Here, though, there is a further, attractive and sound, alternative, although it may mean altering your 'distributor', be it single-bump cam and one pair of points, or twin-bump cam and a single set of points. Instead, what you need is both the twin-bump cam and the twin points. Now fit a double-ended coil to each set of points, and wire each in conventional double-ended fashion, ie, one end to a plug on one cylinder and the other end to a plug on the other cylinder. Now you are not asking too much of either coil, but you will get twin sparks on each cylinder reliably. The idea extends to fours and sixes too, if you can find the appropriate multi-lobe cam and multi-points assembly - and work out exactly the right places to send the extra leads.

How am I going to do Brian’s engine?,

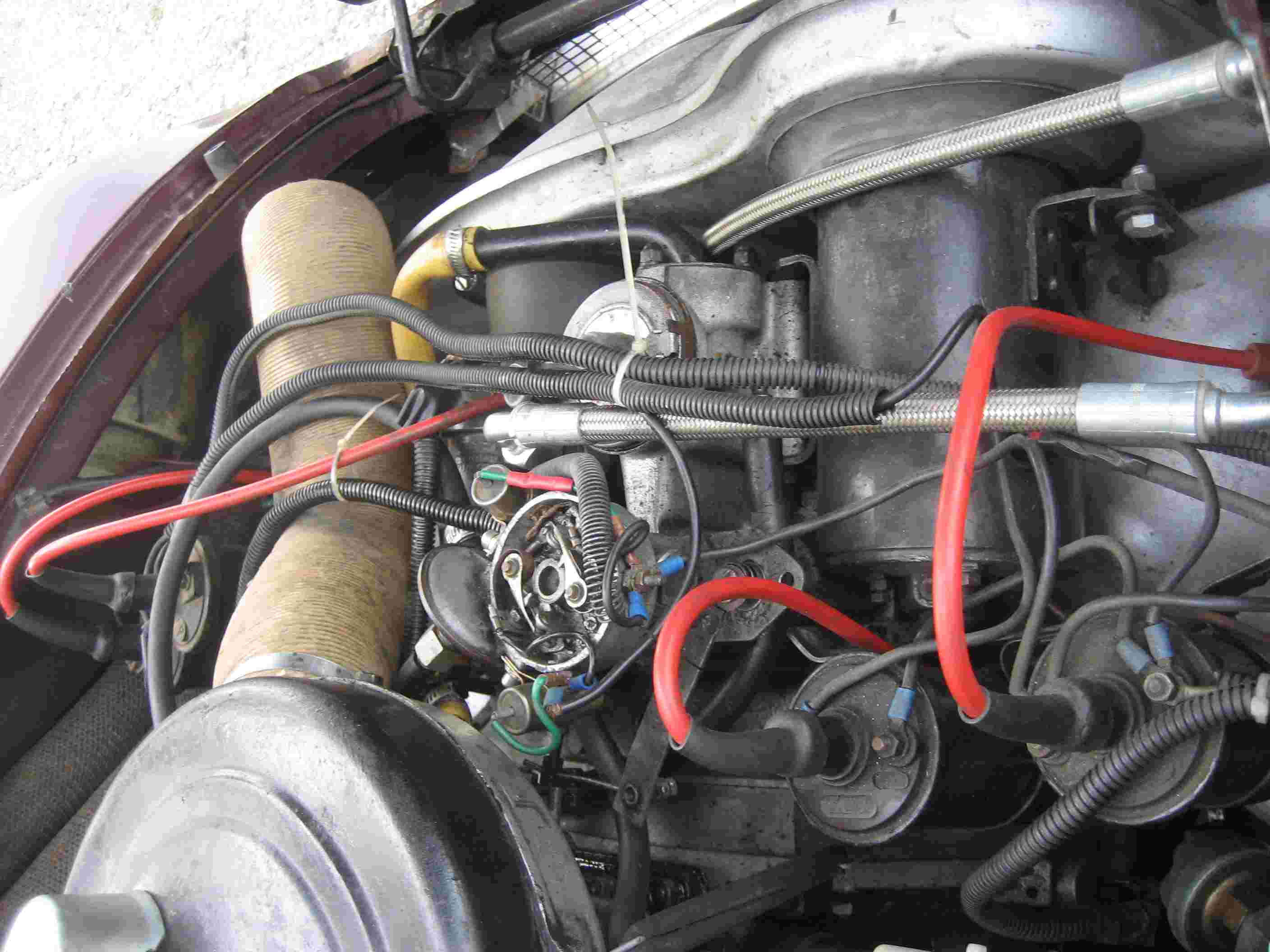

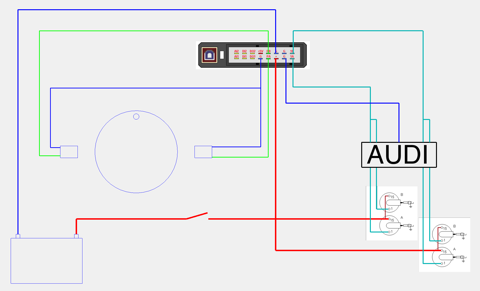

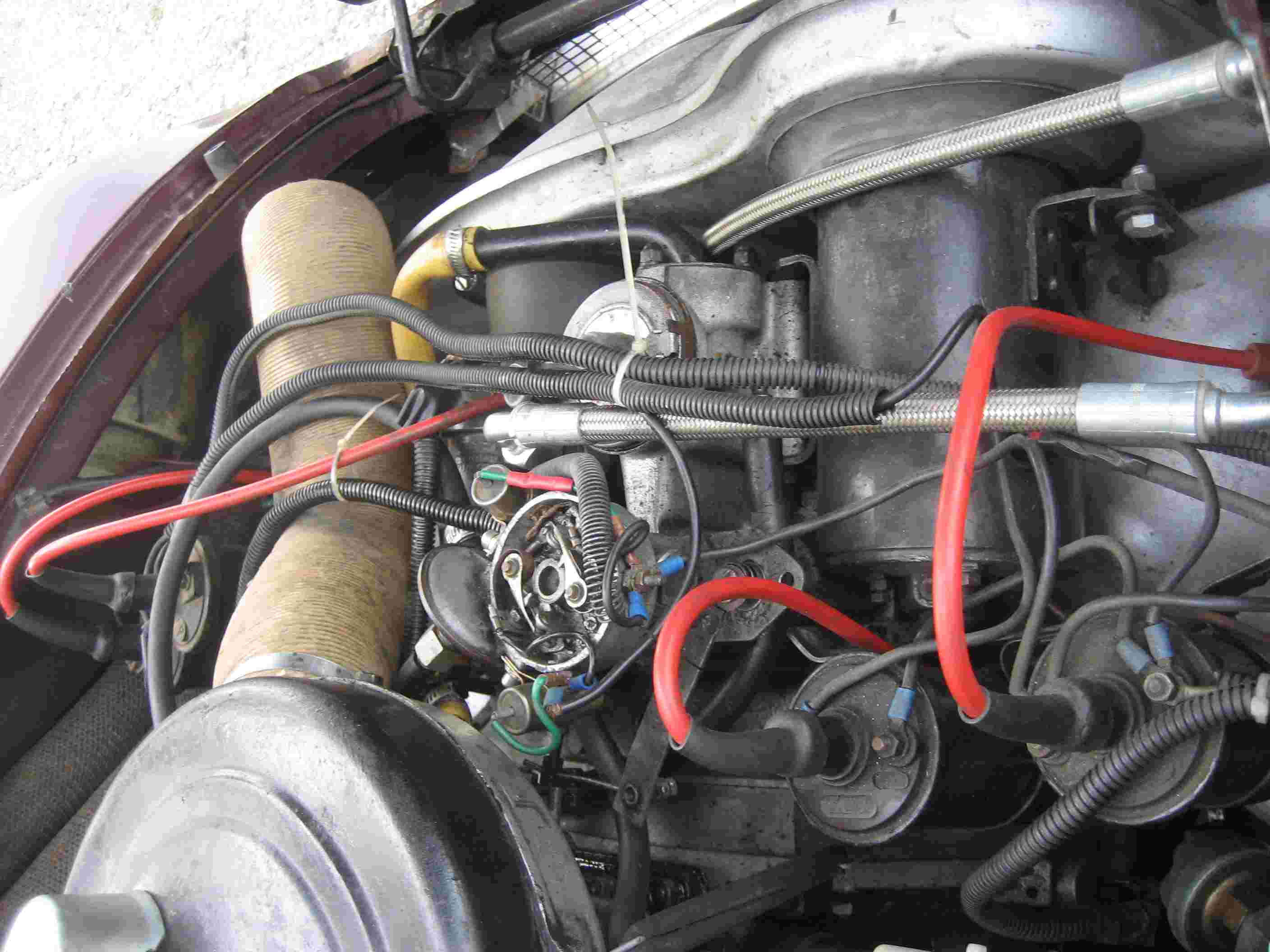

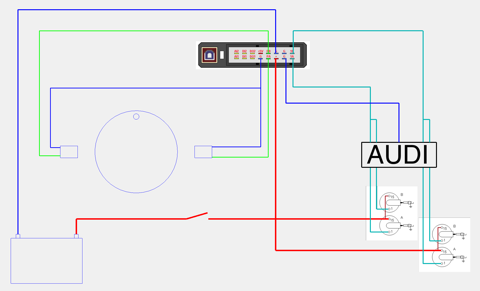

Well it looks like this

I n the above, I am using an Audi ignition control module, which has four inputs & outputs to trigger the GND signals from the programmable ignition module, which in turn feed two single fire coils per cylinder. This now gives a sequential ignition sequence to the firing order, and it should mean there is a good quality spark at all times. The last thing is I cannot use the standard coils I show in the schematic, as the Imfsoft ignition says “standard coils are not supported”, so I have to use modern single fire coils instead.

Incidentally you could do a wasted spark version, using two magnets, one sensor, and using a pair of say double fire coils (2CV, double ended motorcycle types) with one coil feeding the top plugs & the other the bottom plugs. This is essentially what Hampe did, but they were limited by using standard coils & a need to make a failsafe system, that could run of one set of points.

I have managed to get sequential twin spark working in theory using double fire motorcycle coils, but these won’t work because the coil voltage for the spark will be biased towards the cylinder under compression, but hopefully in the next few days a new set of compact twin single fire coils will arrive in the post, so I will find out whether the current draw is too much for the Imfsoft IgnitionTCI 6.1.

To be updated...

Originally, I was going to use stick coils, or pencil coils, but the Panhard heads and torsion bar castings do not lend themselves to a satisfactory fixing solution, plus time is running out, and the added complication of angling the spark plugs, using 10mm plugs and a bespoke adaptor seems like a lot of trouble for little gain.

Historically, Hampe did a wasted system over fifty years ago, using four standard coils, two times two wired in parallel, with an additional contact breaker placed inside the distributor, and an added cam to trigger this second set of points. Nowadays this wouldn’t be required, as you could use the OEM sequential points trigger and a modern ignition control module to switch on the additional coils, but this is digressing slightly.

What are the issues with twin plugging? Well it is nicely summed up here, in this article taken from the Vincent Owners Club if I remember correctly.

Now to sparks. Both Roger Haylett and Gordon Colquhoun want to know about double-ended coils and twin sparks - both having had problems. When fitting twin plugs into a head the concept of using a double-ended coil, fitted into the standard ignition system, may seem ideal, but it doesn't work out. Why? Well, examine where the double-ended coils come from. They are invariably from so-called idle-spark systems, where one cylinder is fired on its compression stroke, and the other end is feeding another cylinder, which will be on its induction stroke (though exactly where depends on whether it is a parallel twin, four, or vee-twin). What you need to know is that the voltage required to make a spark depends on the pressure of the gas it is trying to spark through. So, in an idle spark system, the voltage required is only slightly more than in a single-ended one, because one cylinder is under compression (say 150 psi), but the other isn't (ie, less than 15 psi). So almost all of the voltage appears on the firing cylinder, and a very weak, low voltage spark, occurs in the other one (usually not enough energy even to fire a mixture, which is why it works on vee-twins, which can be well on to the induction stroke, and filling with mixture). Try the same coil on a twin plug head and you need twice the voltage, which is way above the design criteria. So it may not fire reliably.

There are a variety of fixes. Best of the lot is to use a pair of coils in series, to drive the two plugs - preferably a pair of identical-type coils, but they don't need to be better matched than that. Of course, this requires half voltage coils- ok if you can find a pair of six volt ones to run on 12 volt (you might look at 12 volt ones with ballast resistors, and bypass the resistors which makes them six-eight volt types). A number of people have told me that, like Gordon, they have run coils in parallel, but theoretically, it isn't a good idea. Coils in parallel need to balance and so too does the sparking voltage of the plugs. If they don't go off together, then the single spark immediately loads one coil, which may suck power from the primary of the other, and the second spark may not occur. So it probably works better than the original double-ended coil, which misfires completely, but you may actually be running single spark some, or all, of the time, and not, necessarily, firing the same plug every time. Optimising the timing may be impossible, if single and twin optima are different, although the engine will not, necessarily, show ignition problems. However, if it works for you, I'm not going to say it doesn't - but I recommend the series arrangement.

If you are trying to do a Twin, then series or parallel, it makes for a lot of coils. Here, though, there is a further, attractive and sound, alternative, although it may mean altering your 'distributor', be it single-bump cam and one pair of points, or twin-bump cam and a single set of points. Instead, what you need is both the twin-bump cam and the twin points. Now fit a double-ended coil to each set of points, and wire each in conventional double-ended fashion, ie, one end to a plug on one cylinder and the other end to a plug on the other cylinder. Now you are not asking too much of either coil, but you will get twin sparks on each cylinder reliably. The idea extends to fours and sixes too, if you can find the appropriate multi-lobe cam and multi-points assembly - and work out exactly the right places to send the extra leads.

How am I going to do Brian’s engine?,

Well it looks like this

I n the above, I am using an Audi ignition control module, which has four inputs & outputs to trigger the GND signals from the programmable ignition module, which in turn feed two single fire coils per cylinder. This now gives a sequential ignition sequence to the firing order, and it should mean there is a good quality spark at all times. The last thing is I cannot use the standard coils I show in the schematic, as the Imfsoft ignition says “standard coils are not supported”, so I have to use modern single fire coils instead.

Incidentally you could do a wasted spark version, using two magnets, one sensor, and using a pair of say double fire coils (2CV, double ended motorcycle types) with one coil feeding the top plugs & the other the bottom plugs. This is essentially what Hampe did, but they were limited by using standard coils & a need to make a failsafe system, that could run of one set of points.

I have managed to get sequential twin spark working in theory using double fire motorcycle coils, but these won’t work because the coil voltage for the spark will be biased towards the cylinder under compression, but hopefully in the next few days a new set of compact twin single fire coils will arrive in the post, so I will find out whether the current draw is too much for the Imfsoft IgnitionTCI 6.1.

To be updated...

blog comments powered by Disqus