Panhard Cylinder New Liner & Rebore Update 11

09/04/13 22:43 Filed in: Panhard Engine

The boring bar works really well now, but I am running out of time to do Brian’s engine, so I have been looking at other options to reduce the time constraint.

I have researched and got quotes from lminer manufacturing companies in the past, but I recently visited a local cylinder liner company, and was so impressed by their quality, friendliness and pricing, I have decided to have some new liners made for Brian’s engine, and in doing so, test the feasibility of making new ones for future piston batches, and the big bore engine.

I wasn’t planning to do this so soon, but the big bore engine is gathering momentum a little quicker than anticipated, as I have now found a possible forging that is close on 96mm or 1086 cubic centimetres, plus I am simplifying the whole process to make it more cost effective. I am now looking at more expensive pistons, to save on cylinder reworking, and as a bonus it retains the original look of things., and reduces the modification count.

My base philosophy is to make new parts rather than destroy old stock, but in the cylinders case, it’s a little too big of a step to make new ones of these…yet!

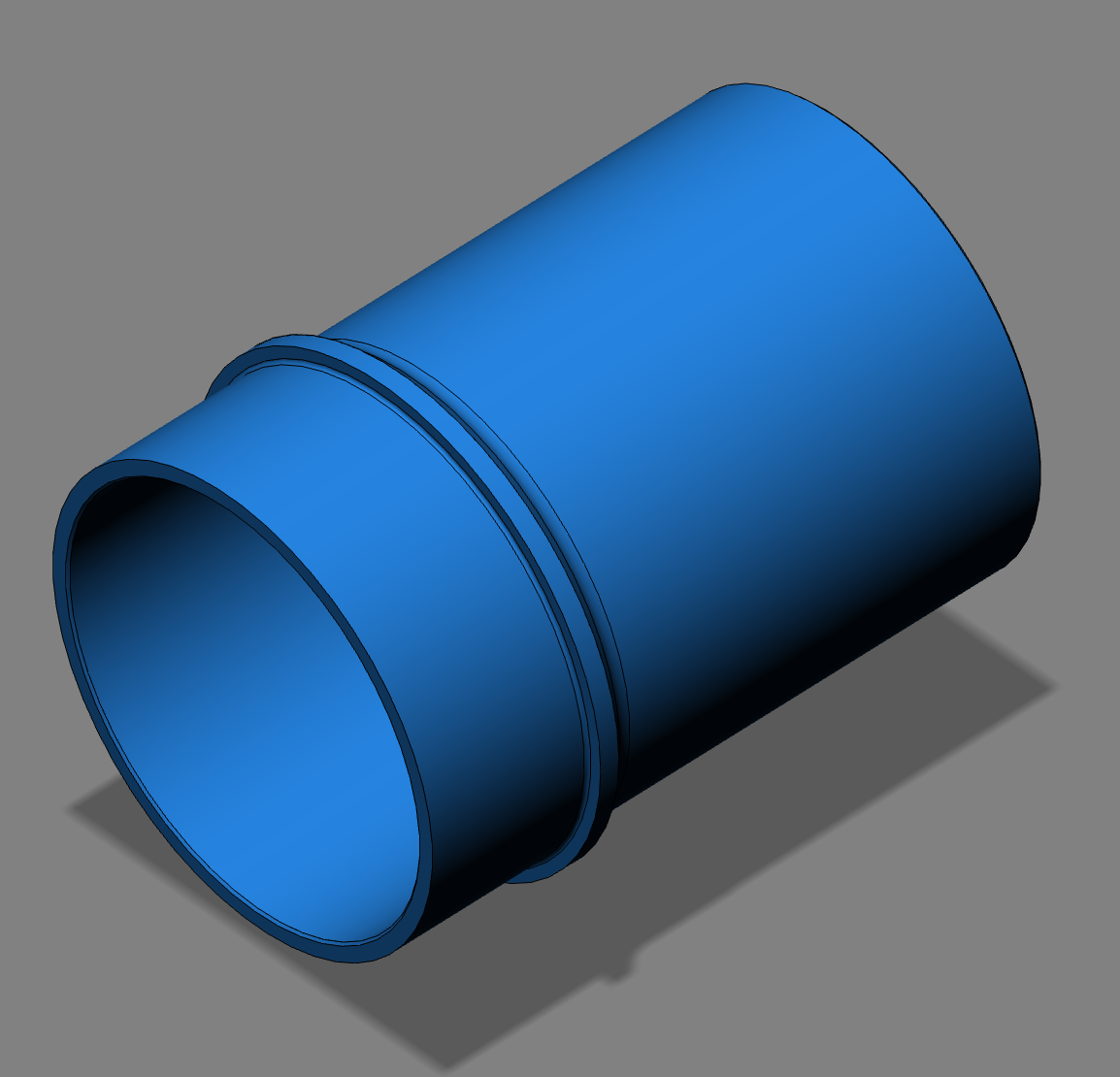

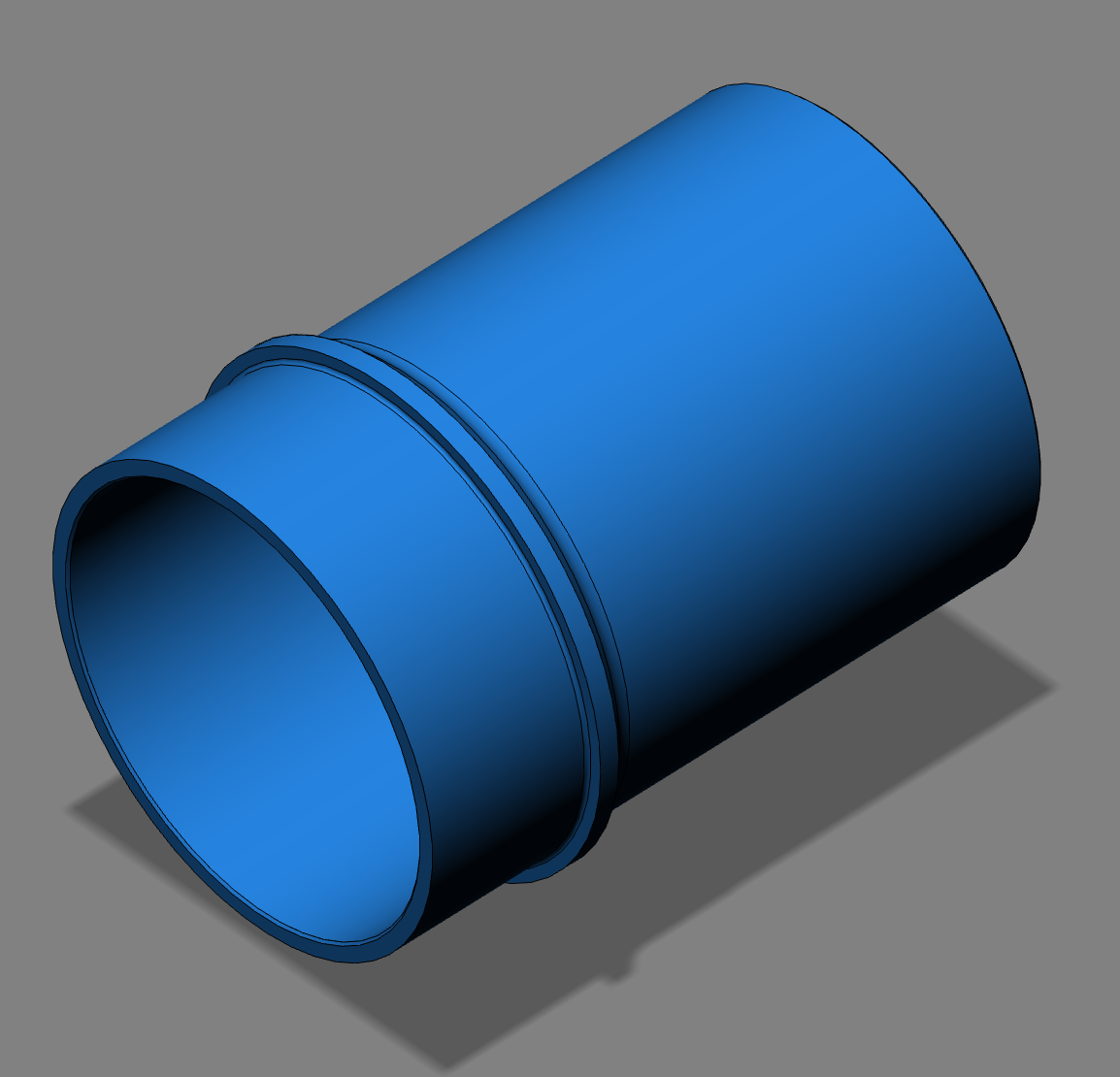

As a result, I have updated the 3D CAD version of the OEM model I did years ago, to fit the new Omega pistons, and sent a 2d & 3D file to the liner company to push this along. I don’t have any orders yet, but these liners will be around £100 each, and be sized & honed to swap into the existing cylinders without any further machining. If anybody else would like bespoke one off liners drop me a line, and I’ll draw them up and arrange manufacture.

The first batch of four will be ready by the end of April according to the company, but the usual lead time is 4-6 weeks, so I grateful they have arranged to speed up the process, and they will be placed in Brian’s engine and hopefully powering us to the 2013 Dutch International.

I have researched and got quotes from lminer manufacturing companies in the past, but I recently visited a local cylinder liner company, and was so impressed by their quality, friendliness and pricing, I have decided to have some new liners made for Brian’s engine, and in doing so, test the feasibility of making new ones for future piston batches, and the big bore engine.

I wasn’t planning to do this so soon, but the big bore engine is gathering momentum a little quicker than anticipated, as I have now found a possible forging that is close on 96mm or 1086 cubic centimetres, plus I am simplifying the whole process to make it more cost effective. I am now looking at more expensive pistons, to save on cylinder reworking, and as a bonus it retains the original look of things., and reduces the modification count.

My base philosophy is to make new parts rather than destroy old stock, but in the cylinders case, it’s a little too big of a step to make new ones of these…yet!

As a result, I have updated the 3D CAD version of the OEM model I did years ago, to fit the new Omega pistons, and sent a 2d & 3D file to the liner company to push this along. I don’t have any orders yet, but these liners will be around £100 each, and be sized & honed to swap into the existing cylinders without any further machining. If anybody else would like bespoke one off liners drop me a line, and I’ll draw them up and arrange manufacture.

The first batch of four will be ready by the end of April according to the company, but the usual lead time is 4-6 weeks, so I grateful they have arranged to speed up the process, and they will be placed in Brian’s engine and hopefully powering us to the 2013 Dutch International.

blog comments powered by Disqus