Panhard ignition update

Wednesday 17 September 2014 Filed in: Panhard Ignition

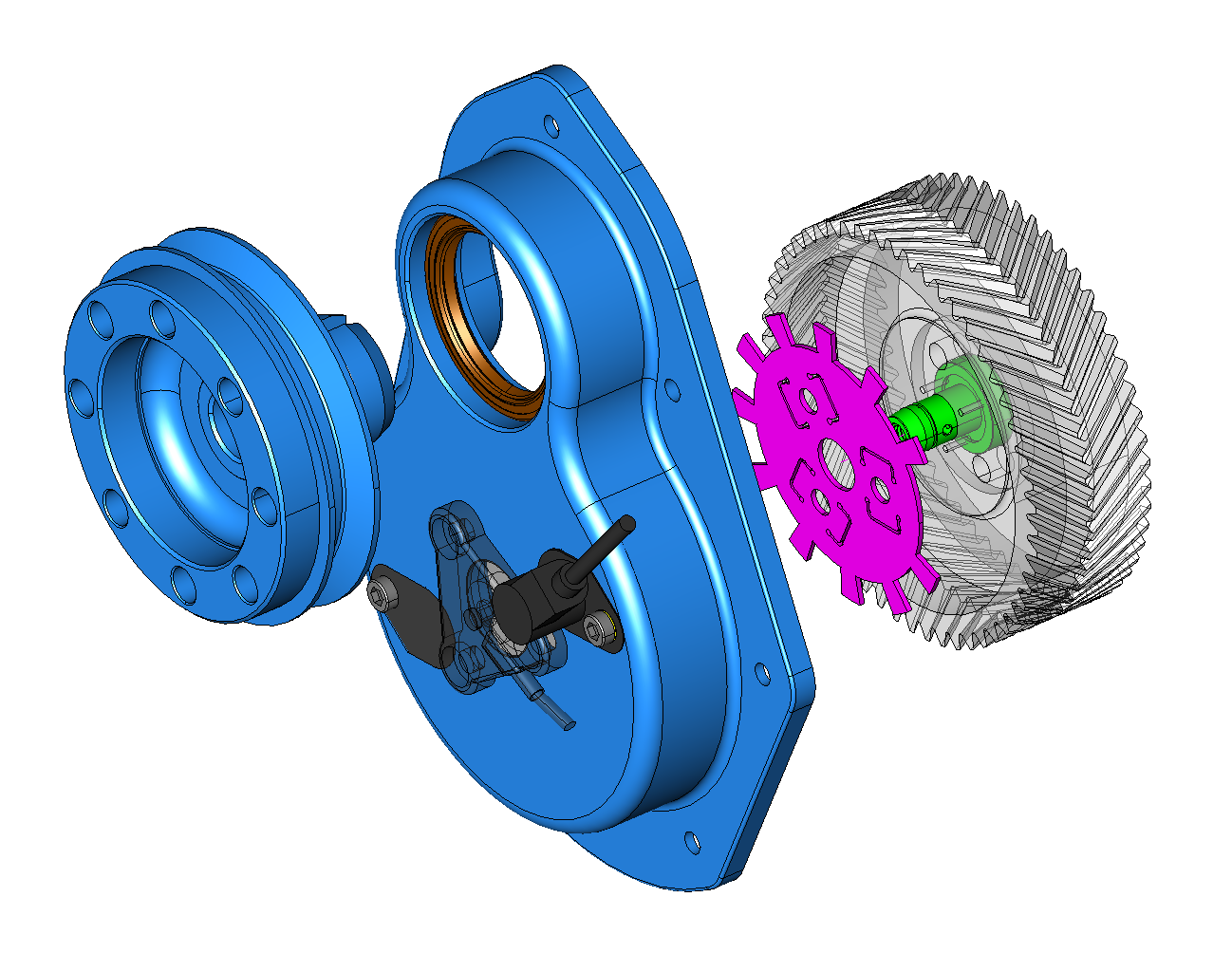

The ignition version of the timing cover has to be reworked, as Imfsoft do not make the Direct Ignition TCI model anymore, but a new unit called the Master Mini 3TCI. To adapt my existing two sensor covers I have made a blanking plug, and the thoughts at the moment are, that only one or no hole version of the cover will be produced, with a distinct possibility that the plain cover will be the ignition variant with a blanking plug fitted.

Here’s how it looks at the moment...the V pulley is an optional part, for those that cannot modify the front pulley themselves.

The timing cover is primarily a front seal upgrade option, so the ignition aspect is a secondary upgrade.

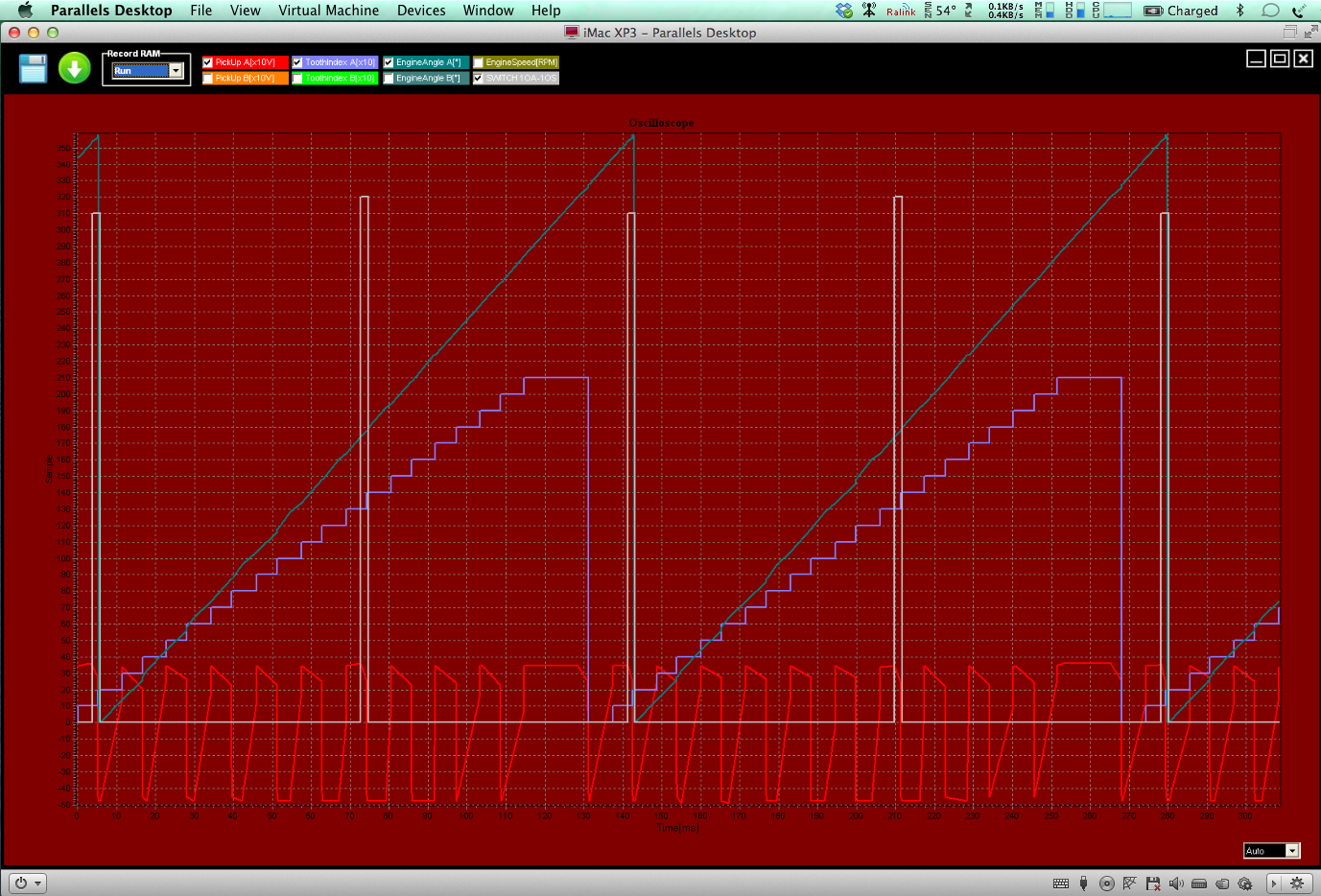

The Imfsoft Master Mini 3TCI has been bench tested and produces very good results, as can be seen here. The red waveform at the bottom is the teeth from the trigger wheel, the light blue “stairs” that step upwards are the incrementing trigger events, and these need to be regular steps. The diagonal greenish line is the processor interpreting the wheel, and the software is checking that these are the correct spacings. The white columns are twice per camshaft revolution and are the ignition events that trigger the coils.

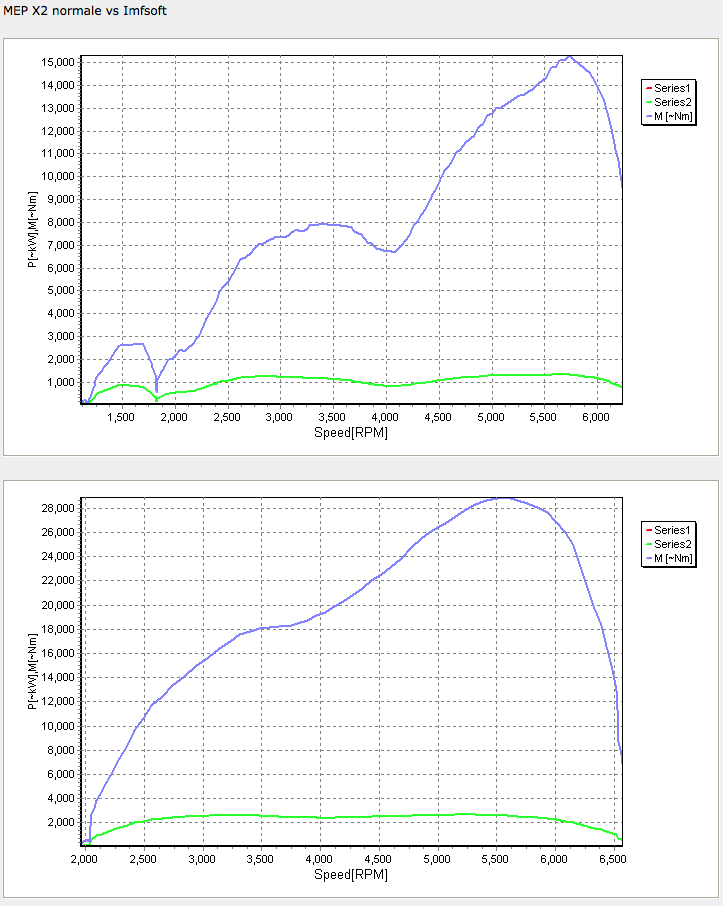

At the moment, I don’t have a working engine, so I have fitted the Imfsoft to an MEP X2 recently. This used the earlier Imfsoft unit, but it has a very useful “dyno” function. The units are meaningless on the right hand side representing “Power”, but the shaping of the curve is representational. The first one is a standard Panhard M8S engine fitted with the original vacuum & centrifugal advance system, and the next curve is the first Imfsoft run where a modified advance curve affected the power output of the engine.

Early days yet, but interesting to say the least, and it backs up my earlier research with Ron Tyrrell’s PL17 where I modified the distributor. I could get a change in part throttle performance at the expense of full throttle or cruising. The mechanical system isn’t able to cope with the demands of the engine, whereas a correctly set up programmable system is.

Watch this space...

blog comments powered by Disqus