Mar 2012

Panhard crankcase front oil drilling reinstated

04/03/12 15:09

Next up to bring Brian’s engine up to date with the oil supply modifications is restoring the original designs original oil supply mods, but this time bypass all the negatives.

The later engines didn’t have this option, as can be seen here.

(insert picture)

The original engines had this oil feed visible above the camshaft bore at the very front of the crankcase, which is shown below. As the camshaft rotates this drilling is filled two times per camshaft revolution, and after this it passes underneath the bearing and jumps into the slingers. Some oil splashes back and passes through the main bearing, but the rest is accelerated by the slingers on the crank web, and passes through the big end bearing before exiting and splash lubricating the little end.

Unfortunately this hole is too small, and it led to a 50% reduction in flow rate over the rear, which is why I mod the front like so.

It might not be obviously apparent from this picture, but the hole size is now 6mm diameter, whereas the one above is just 4mm. This new oil feed now matches the camshaft aperture, so all openings, front and rear are timed equally. The 4mm diameter hole in the middle will have to be enlarged to 5mm, as the rear oil feed is actually 5mm in diameter, but at first it is more important to get the hole in the right position, and work from this.

Oil feed at 5mm diameter now, which is 50% bigger than OEM, but matches the rear bearing oil supply.

The later engines didn’t have this option, as can be seen here.

(insert picture)

The original engines had this oil feed visible above the camshaft bore at the very front of the crankcase, which is shown below. As the camshaft rotates this drilling is filled two times per camshaft revolution, and after this it passes underneath the bearing and jumps into the slingers. Some oil splashes back and passes through the main bearing, but the rest is accelerated by the slingers on the crank web, and passes through the big end bearing before exiting and splash lubricating the little end.

Unfortunately this hole is too small, and it led to a 50% reduction in flow rate over the rear, which is why I mod the front like so.

It might not be obviously apparent from this picture, but the hole size is now 6mm diameter, whereas the one above is just 4mm. This new oil feed now matches the camshaft aperture, so all openings, front and rear are timed equally. The 4mm diameter hole in the middle will have to be enlarged to 5mm, as the rear oil feed is actually 5mm in diameter, but at first it is more important to get the hole in the right position, and work from this.

Oil feed at 5mm diameter now, which is 50% bigger than OEM, but matches the rear bearing oil supply.

Panhard crankcase camshaft gear oil level

04/03/12 12:24

A little mod that improves oil quality, reduces heat build up in the oil, and improves pumping losses to the engine. At the moment the Panhard timing case oil level is determined by the hi level drainage points shown here or leaking past the front main bearing.

Normal practice for a splash lubricated gear is to have no more than a third of gear diameter immersed, so why Panhard did this surprises me. Originally they had a fibre wheel of massive proportions meshing to a hardened steel gear, and in all fairness it probably didn’t need much lubrication. Brian’s engine has a dural gear fitted, a specialised aluminium alloy version, that available from most Club sources, and it is made in France.

These new drillings, now restore the status quo, and at the same time allow for this area to get some oil changes. Technically these wouldn’t get fully drained, unless the steel timing cover case was removed, because there is no low level return point. I think it is realistic to revise this mod and lower the oil level further, but as this is the third engine I have modded, I will wait until I get some better feedback on the wear characteristics before doing so.

Next up is restore the crankcase oil drilling that originally existed, before Panhard revised it. I need to get a long series drill to do this properly, as the entry angle into the casting, means the drill chuck would catch otherwise.

Normal practice for a splash lubricated gear is to have no more than a third of gear diameter immersed, so why Panhard did this surprises me. Originally they had a fibre wheel of massive proportions meshing to a hardened steel gear, and in all fairness it probably didn’t need much lubrication. Brian’s engine has a dural gear fitted, a specialised aluminium alloy version, that available from most Club sources, and it is made in France.

These new drillings, now restore the status quo, and at the same time allow for this area to get some oil changes. Technically these wouldn’t get fully drained, unless the steel timing cover case was removed, because there is no low level return point. I think it is realistic to revise this mod and lower the oil level further, but as this is the third engine I have modded, I will wait until I get some better feedback on the wear characteristics before doing so.

Next up is restore the crankcase oil drilling that originally existed, before Panhard revised it. I need to get a long series drill to do this properly, as the entry angle into the casting, means the drill chuck would catch otherwise.

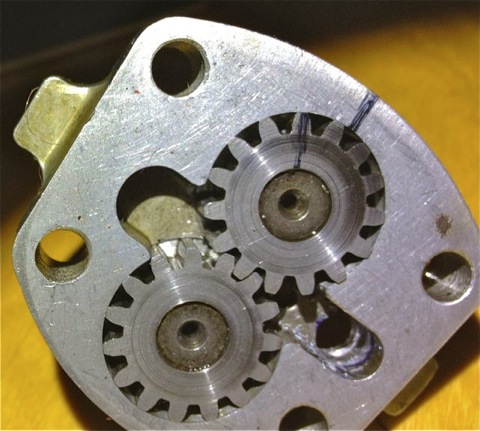

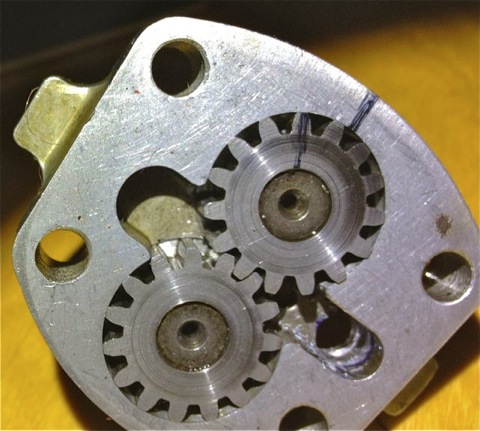

Panhard oil pump modification

04/03/12 08:06

The oil pump before

This modified oil pump will now flow more oil at speed, when you want it and there will be less bubbles in the oil as a result, which has the effect of improving the oil quality.

You can see the small inlet pipe into the crankcase, and also see where the oil pump mates up to it, which is the black circle I have inked in and the centre of the outlet is represented by the black lines. So again the flexible shaft is used to reshape this area, and the important thing is to match the mating diameters more closely. It makes sense to machine and open up this drilling to match the oil pump, as this will increase the flow rate into the main oil galleries, and it has no effect on the pressure of the system, contrary to what you might think. The pressure in the unmodified camshaft is controlled by the cross drilling after this, and the cylinder head feeds likewise by the size of their respective openings too. It really doesn’t make sense not to do it.

Next up revising the front crankshaft feed

This modified oil pump will now flow more oil at speed, when you want it and there will be less bubbles in the oil as a result, which has the effect of improving the oil quality.

You can see the small inlet pipe into the crankcase, and also see where the oil pump mates up to it, which is the black circle I have inked in and the centre of the outlet is represented by the black lines. So again the flexible shaft is used to reshape this area, and the important thing is to match the mating diameters more closely. It makes sense to machine and open up this drilling to match the oil pump, as this will increase the flow rate into the main oil galleries, and it has no effect on the pressure of the system, contrary to what you might think. The pressure in the unmodified camshaft is controlled by the cross drilling after this, and the cylinder head feeds likewise by the size of their respective openings too. It really doesn’t make sense not to do it.

Next up revising the front crankshaft feed

Panhard crankcase oil circulation faults (revisited)

03/03/12 12:50

A quick history lesson on Panhard engine failures. The front main bearing and front cylinder crankshaft big end started to develop failures, as they increased the horsepower. It was attributed to insufficient oil supply, and so the front end lubrication was revised, and the camshaft timing gears were used as a splash lubrication system and the oil drilling that provided that role under the front main bearing was removed. This modification was introduced from around the early 1960’s, and ran to the end of production in 1967.

This engine is the later type, so needs modifying back to the original oil supply route, but adding the improvements necessary to negate the other faults. The first area to tackle is the front end crankshaft oil supply, so plugging the newer oil drillings and creating a matched new one under the front main bearing housing. These will be fixed with Loctite once all the drilling has finished and the crankcase has been thoroughly cleaned.

Plugging the timing gear lubrication drilling, so restoring equal phasing, but fitting a new design of oil light piston to replace this function.

Later I will reduce the oil flow in the timing gear casing, so reduce pump losses, and oil degradation. On examination the deposits in the slingers at the front part of the crankshaft are almost double those at the rear, which is due to the oil supply being much greater and the timing gear casing is a residue trap, because it cannot drain away and be refreshed.

This engine is the later type, so needs modifying back to the original oil supply route, but adding the improvements necessary to negate the other faults. The first area to tackle is the front end crankshaft oil supply, so plugging the newer oil drillings and creating a matched new one under the front main bearing housing. These will be fixed with Loctite once all the drilling has finished and the crankcase has been thoroughly cleaned.

Plugging the timing gear lubrication drilling, so restoring equal phasing, but fitting a new design of oil light piston to replace this function.

Later I will reduce the oil flow in the timing gear casing, so reduce pump losses, and oil degradation. On examination the deposits in the slingers at the front part of the crankshaft are almost double those at the rear, which is due to the oil supply being much greater and the timing gear casing is a residue trap, because it cannot drain away and be refreshed.